Quality management directly reflects the management level of an enterprise, in the manufacturing industry in recent years, the enterprise of upstream supplier factories, the requirements of the production process "strict", quality management has become the appraisal of the upstream supplier or shortlisted for the basic conditions,

From the gold medal in the SAP partner today, d the digital solutions experts Yu Shiping teacher, will control the quality of the challenges facing the manufacturing industry, for you to explain how to use in manufacturing ERP, SAP Business ByDesign, achieve high quality track trace management, optimizing production management mode, to strengthen the process management and control, improve the quality of management, operation, remarkable achievements

Manufacturing ERP quality recommend

SAP Business ByDesign set SAP nearly 50 years of experience in the enterprise information, is the world's most complete, the most flexible on-demand customized enterprise management SaaS cloud solutions, embedded in the manufacturing enterprise need, end-to-end 36 Business processes, from Business opportunities to the final customer service all covers,

At the same time, the SAP Business ByDesign support enterprise collectivization, internationalization development needs, the enterprise in the process of going abroad, don't worry about the solution now, with its internationalization and knocked out, in turn, we provide manufacturing ERP platform, from the power of the language localization requirements of fiscal and taxation system, can provide strong support for enterprise Business development of globalization,

If you have any requirement in the aspect of collectivization, SAP Business ByDesign can realize collectivization management, for example we unified master data on manufacturing ERP platform, unified legal person company set, unified group finance merger offset processing, including the merger after offset, the conventional group financial reports, etc.,

At the same time, the SAP Business ByDesign have top analysis and reporting tools, to achieve "everyone can do report" such a concept -- each user can be based on the enterprise data, in manufacturing ERP implement drag-and-drop reporting, no longer need to put the data into Excel in secondary processing, of course, if the enterprise like in Excel data extract, can also use the embedded system based on Excel reporting tools, reporting,

SAP Business ByDesign quality management of the Business scenario

Next, we focus on manufacturing enterprise how to use SAP Business ByDesign solution, using manufacturing ERP implementation for each production link of real-time control,

First for quality inspection, involves the purchase of qc, production, inspection, sales of quality supervision, inspection and so on, in the system through the inspection process, final and warehouse department in synergy, here to be without some important documents, namely we often say that the inspection and quality inspection sheet, as well as the inspection quality inspection qualified after the nonconforming product is put in storage or direct material return process,

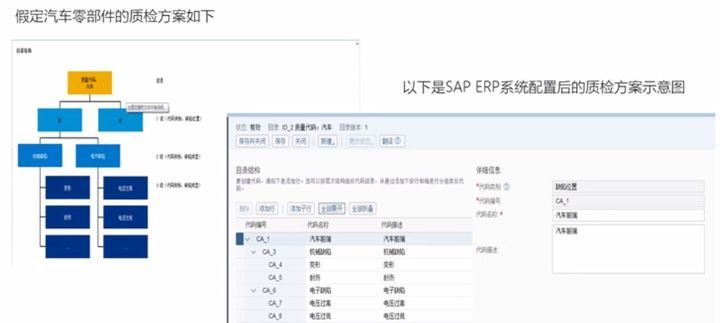

Above listed manufacturing ERP in a auto parts quality inspection plan, shows the SAP Business ByDesign platform how to configure the quality control plan, in the left half is car inspection code, it will be according to the different parts of the enterprise requirements - have all inspection, defect inspection (sampling), and what each inspection inspection, such as car have specific mechanical defects, we can check the deformation conditions, simple brush situation and so on, this is a quality inspection within the platform, is how to design the layer by layer,

Secondly, in view of the serial number management, SAP Business ByDesign very flexible provides serial number management model,

Enterprise can according to the actual need to confirm the serial number management, can choose on different documents or business scenarios, serial number input, also can choose not to all the business scenario input serial number, integrated all sorts of data, by a special department to assign a code for each product serial number, so that both can make the necessary serial number input, and can reduce the unnecessary tedious operation,

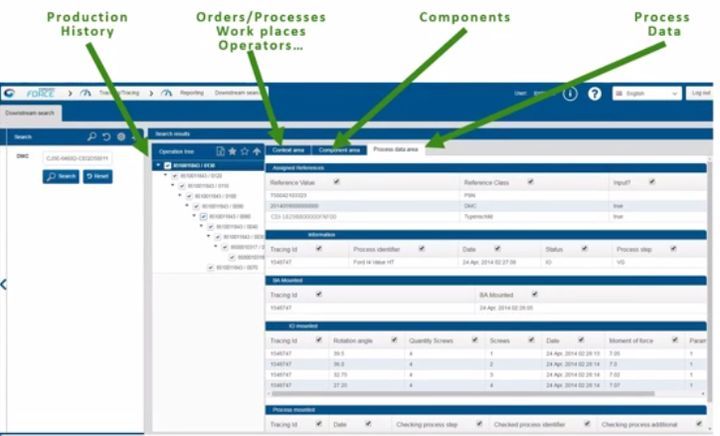

Finally around the tracing management of production and processing process, in the production process, key parts with traceability management requirements, how to realize the forward and reverse traceability? We want to complete a trace, the source is the production data of execution, production data source is the scheduling of execution issued production work order, the source of the production work order is we create production orders in manufacturing ERP,

In batches, for example, after the completion of the purchase, it will produce a batch code, produced after the batch code, as the acquisition process, the specific process of assembly, of course, some of them are semi-finished products, to put it together again, become the final assembly of the finished product, it is under the specific examples, it forward or reverse trace process,

In the end, the result is that we see above manufacturing ERP trace levels of the tree, on the analysis of a certain product, you can clearly see each TAB in the corresponding data, it is through the quality control modules, realization of master data to the repair order charge, charge to the trading, to an aggregation of individual, enterprise in SAP Business ByDesign system within an interface, can check out by different TAB need to trace back any detailed information,

Conclusion

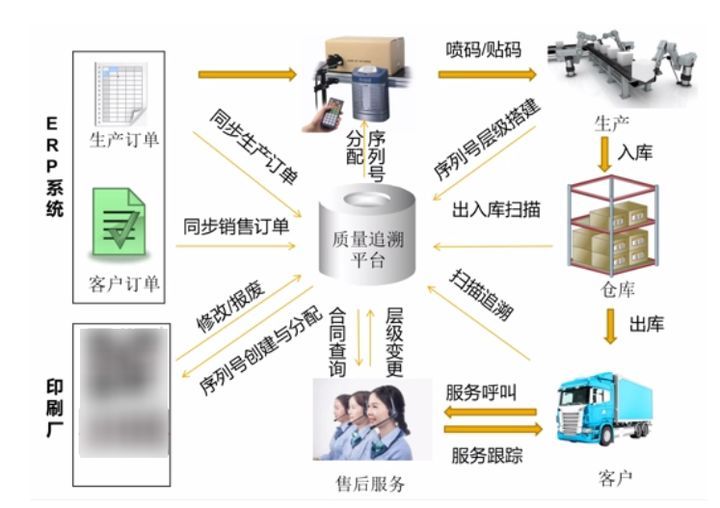

If in the concept of platform, the dimension of the provide manufacturing ERP solution achieved from SAP Business ByDesign system to the customer, printing plant, after-sales service, every link of the tracking tracing management - within the manufacturing ERP implementation serial Numbers generated by the production orders, the spurt the code it to specific equipment, the equipment need to undertake the corresponding assembly, outbound and inbound process, during this period, the enterprises in the system to achieve the initial scanning and serial number level structures, complete serial number tracking back,

After the goods sent to the customer, the enterprises through the manufacturing ERP can be traced back to send the serial number of the customer specific products, when the goods have a problem, through a service call, you can query to the serial number on the contract, and it used hierarchy, if around service call, the after-sales service tracking tickets, enterprise can this service for tracking tickets, trigger manufacturing ERP service process, and eventually around the service request form parts back, and the corresponding fiscal integration documents,

If, in the process of tracing code appear problem, need to modify or reporting, enterprise can through the SAP Business ByDesign platform printing, also can through the printing plant, at the time of scanning confirmation tracking back yards, paste to the core components,

Above is the SAP Business ByDesign system set up complete quality traceability platform, through manufacturing ERP each core Business processes together, the whole content of power equipment manufacturing enterprises to achieve quality traceability,

Visible, in the future if you want to continue to enhance the competitiveness of the manufacturing in our country, should focus on enhance the added value of the high technology manufacturing industry, this is to make the key to maintain a rapid growth of economy in our country, is also the dimension of the manufacturing industry has been for the direction of ERP,