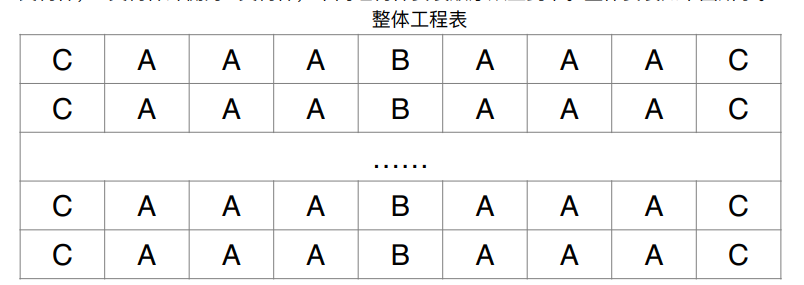

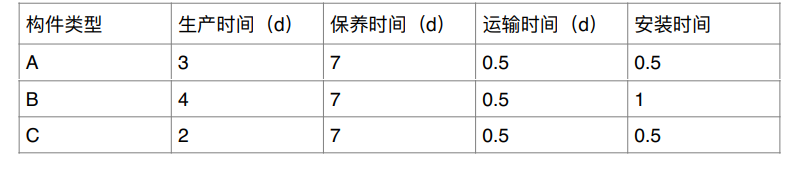

Three components are all manufactured in the factory, the factory has five production location, can produce A, B, C three kinds of artifacts, after the completion of the production need maintenance to get to the scene out of the workshop for installation, maintenance work stations, A total of 40, production time, the maintenance time, transportation time, installation time shown in the table below,

solve the problem of algorithm 1:

The project starts on March 1, 2021, needs to be completed in June 30 2021, please prepare the algorithm to realize automatic component plan arrangement (with completed time accurate, don't consider redundancy).

solve the problem of algorithm 2:

Due to the project there are difficult to solve the problem, the installation after the 12 groups (row) components, cause the overall engineering middle column in the table following 12 C component cannot be installed, please install the group member 12 has completed time point of the beam field production situation, production situation and make this clear inventory (best illustration), and the input system and generate a new automatic arrangement plan,

algorithm solution 3:

According to the actual production condition, the production location and maintenance of the factory location quantity adjustment, implementation into less as far as possible the number of station still can satisfy actual demand of the construction of the most efficient,