A. T3ster and characteristics of

Thermal transient tester T3Ster, advanced thermal characteristic test instrument for semiconductor devices, at the same time to test the IC and SoC and SIP, radiator, heat pipe thermal characteristics, such as

1. Both JESD51-1 define the Static test method (Static Mode) and the Dynamic testing method (Dynamic Mode), real time acquisition device transient temperature response curves (including the heating curves and cooling curve), the sampling rate is as high as 1 millisecond, testing up to 1 microsecond delay time, junction temperature resolution as high as 0.01 degrees,

2. Can test the steady state thermal resistance, can also test the transient thermal impedance,

3. Meet the JEDEC latest crust thermal resistance (theta jc) test standard (JESD51-14),

4. Test methods in accordance with IEC 60747 series standards,

5. Meet the international standard JESD51-51 of LED and LED light heat integration testing standard JESD51-52,

6. Test methods in accordance with MIL - STD - 883 - h method 1012.1 and the requirements of MIL - 750 e series 3100,

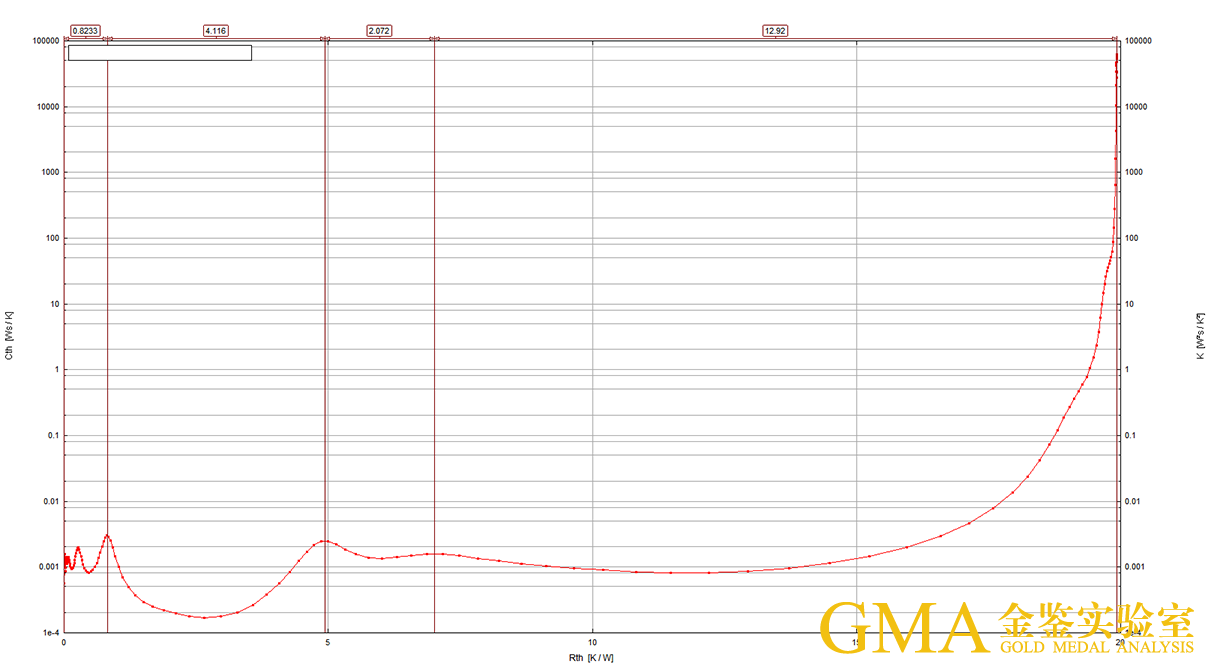

Structure function analysis method, to analyze thermal properties of each layer structure device heat conduction path (thermal resistance and heat capacity parameters), the equivalent thermal model building components,

8. Can and thermal simulation software Flotherm, FloEFD seamless combination of the actual testing device of thermal parameters for subsequent import simulation software simulation optimization,

Test related parameters of LED products:

Substrate temperature: room temperature to 90 degrees

The minimum sampling time interval: 1 mu s

0.01 degrees junction temperature testing resolution:

Typical voltage measurement resolution: 12 mu V

2. T3Ster system specification

1. Heating power: 0 to 10 a/150 v (current linear adjustable), satisfy the high power high voltage LED products testing;

2. The current range: 0-10. A, linear output;

3. The device voltage: 0-150 - v;

4. The current accuracy: 0.05%;

5. K coefficient test current: 0-200 ma (current linear adjustable), and the external temperature control device, automatic test K coefficient;

6. The current range: 0-200 ma, linear output;

7. The device voltage: 0-150 - v;

8. Current accuracy: 0.05%;

9. The Gate voltage control: 0-10 v (linear adjustable);

10. The voltage range: 0-10 v;

11. Voltage accuracy: 0.05%;

12. The heating condition to test state switch time: 1 s.

13. With circulation pulse output function: output pulse cycle times can be set up once to countless times;

14. The temperature test method: ETM testing method (device conduction voltage as temperature sensitive variables), compatible with the three test standard: JEDEC (JESD51-1, JESD51-14, JESD51-50, JESD51-51, JESD51-52), MIL - STD - 750 - e, IEC60747;

15. Transient thermal test method: provide two test method: static testing method (continuous heating, heat balance, the cooling in the continuous test); Dynamic test method (pulse heating, single point test);

16. The voltage sampling rate: 1 us/time;

17. Temperature sampling accuracy: 0.0006 degrees (voltage resolution 12 uv mode);

18. The transient thermal test is completed, the output of the thermal resistance network model of the heat capacity can be used by thermal simulation software, the simulation analysis;

19. Through the analysis software available internal organization function, the structure function reflects from the heat source (origin) to the environment (last part) straight upward toward the heat flow path of all the heat capacity and thermal resistance on the distribution, according to the structure function on the slope (the ratio of the heat capacity and thermal resistance) change, can distinguish between different materials, in an intuitive way, different materials to help analyze the cooling path of thermal resistance and heat capacity;

20. Light, heat, electricity joint test, can cooperate with integrating sphere and optical test host in the light, heat, electricity joint tests;

21. The thermocouple measurement accuracy: +/- 0.5 degrees;

22. The hot temperature measurement range: -- 50 ~ 200 degrees;

23. The thermal resistance measurement range: 0 degrees - 1000 degrees/W/W;

24. The temperature control device for temperature control range: 5 degrees to 90 degrees, temperature stability ﹢/- 0.2 degrees,

3. The application scope and function of the T3Ster

1. The scope of application:

(1) all kinds of transistors, diodes and other semiconductor discrete devices, including: common semiconductor thyratron, bipolar transistor, as well as the high power IGBT, MOSFET, leds and other components;

(2) the various complex IC and MCM, SIP, SoC and other new type of structure;

(3) a variety of thermal characteristics of the complex heat dissipation module testing, such as heat pipe, fan, etc.,

2. The function:

1) semiconductor device junction temperature measurement;

A semiconductor device (2) the steady state thermal resistance and the transient thermal impedance measurement;

(3) semiconductor devices thermal resistance and heat capacity measurement, given device structure of the thermal resistance of heat capacity (RC) network structure;

(4) semiconductor devices encapsulate internal structure analysis, including the sealed device structure of each layer (layer chip + welding + heat sink, etc.) of the thermal resistance and heat capacity parameters;

(5) semiconductor devices aging test analysis and packaging defects diagnosis, help users to accurately locate the defect structure of the sealed;

6. Material thermal characteristics measurement (coefficient of thermal conductivity and specific heat);

All landowners contact thermal resistance measurement, including heat conduction glue, thermal conductivity test of new thermal contact materials,

4. Test methods - the thermal transient testing technology based on electrical

1. The test method, electric method

Looking for device internal temperature sensitive characteristics of electrical parameters, by measuring the change of the temperature sensitive parameters (TSP) to get the change of the junction temperature,

TSP choice: general selection devices within the positive junction voltage of PN junction,

2. Testing technology: thermal transient test

(1) when the power of the device changes, junction temperature of the device from a thermal steady state to another steady state, T3Ster will record the change of the junction temperature transient process (including heating and cooling process),

(2) a test, can get steady state of the junction temperature resistance data, also can get junction temperature curves of the transient change over time,

(3) the transient temperature response curve contains a heat conduction path of each layer of the structure of the detailed thermal information (thermal resistance and heat capacity parameters),

Note: the technical consultation please contact the blogger, thank you!