Connection ACS510 inverter configuration cases

The configuration case for wuxi Emerson turn Modbus Profinet gateway (MCN - PN3001) panasonic ACS510 inverter access PLC of Siemens 1200

Need equipment: Siemens PLC1200, turn ACS510 inverter, wuxi Modbus Emerson Profinet gateway

Configuration methods:

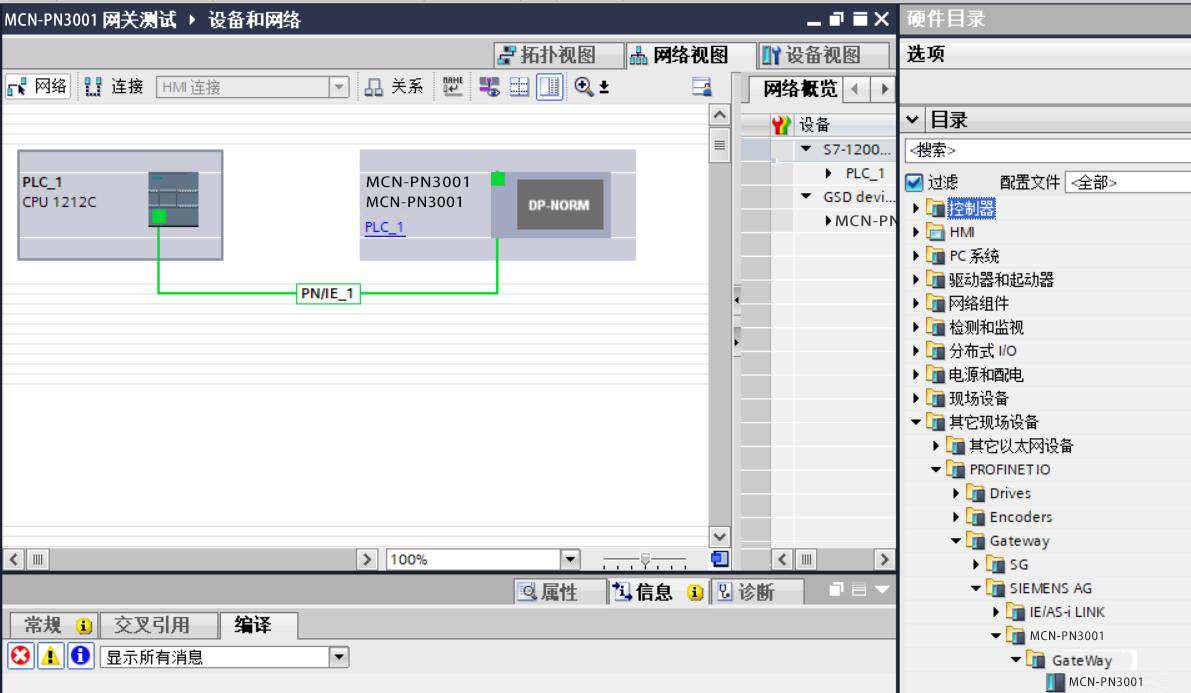

Open bo figure, new project and add the GSD file,

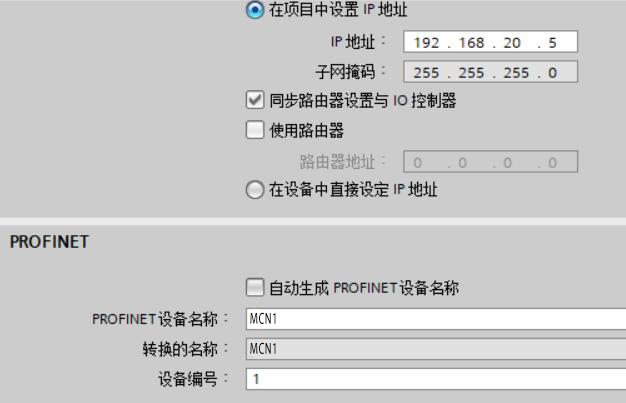

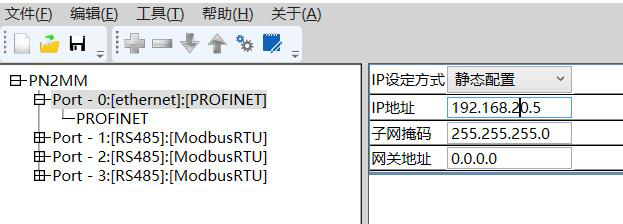

Profinet connection, set the wuxi Emerson Modbus profinet gateway IP address and device name, IP and gateway that keep in the same network segment,

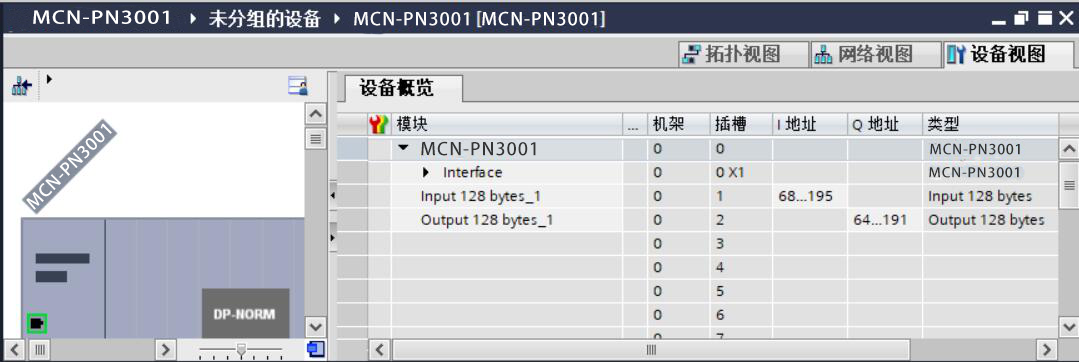

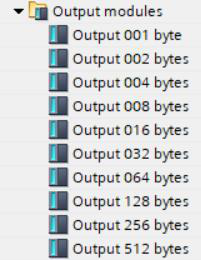

Enter the device view selection length of the total number of input and output according to

From the right hardware directory to add the selected length (wuxi Emerson turn Modbus Profinet gateway )

Download the configuration to the PLC

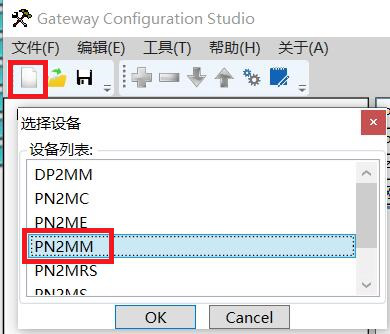

Open the wuxi Emerson Modbus Profinet gateway configuration software for Modbus parameters configuration, click the red circle in the new, choose PN2MM

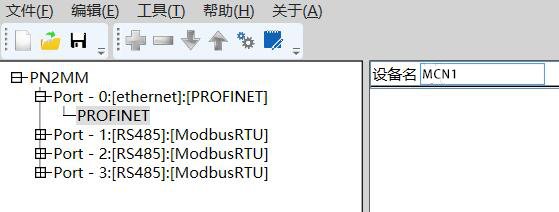

Set the wuxi Emerson turned Modbus Profinet gateway (MCN - PN3001) name, IP address, and equipment to be consistent and PLC configuration

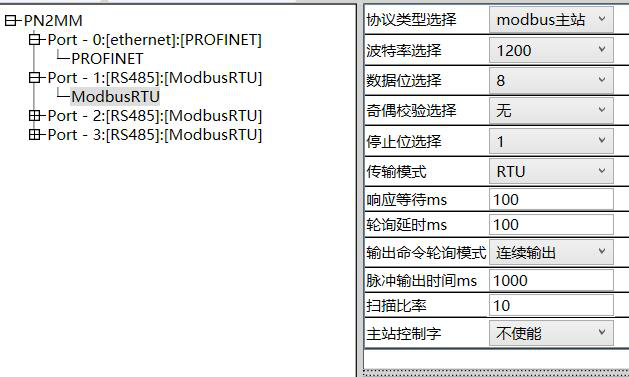

Set of wuxi Emerson Modbus Profinet gateway (MCN - PN3001) parameters of 485 baud rate, data bits, parity to and from the station to remain consistent,

Response to wait for and polling delay according to adjust the time interval from the station equipment, if from standing up the response speed is slow response latency, if request waiting for a period of time after reply from the station to receive the command, then the polling delay must be large

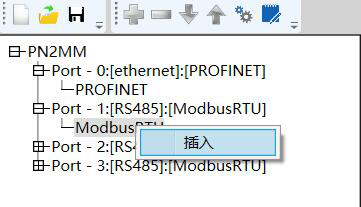

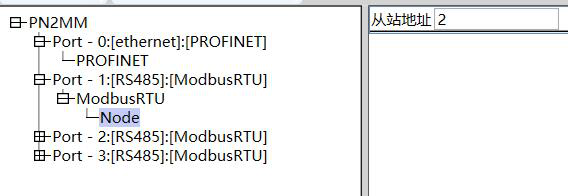

Right-click on the Modbus RTU inserted in the lower menu, click on the Node number fill out from USA

Continue to right click on the insert

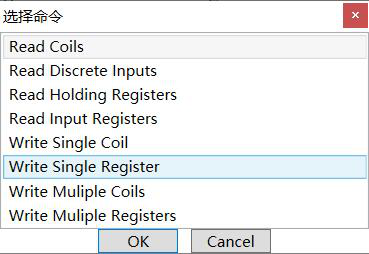

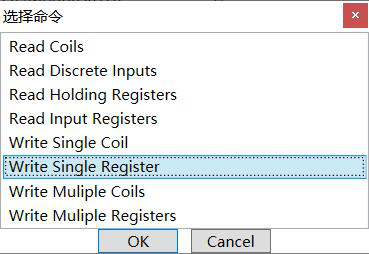

According to different needs to choose the required function

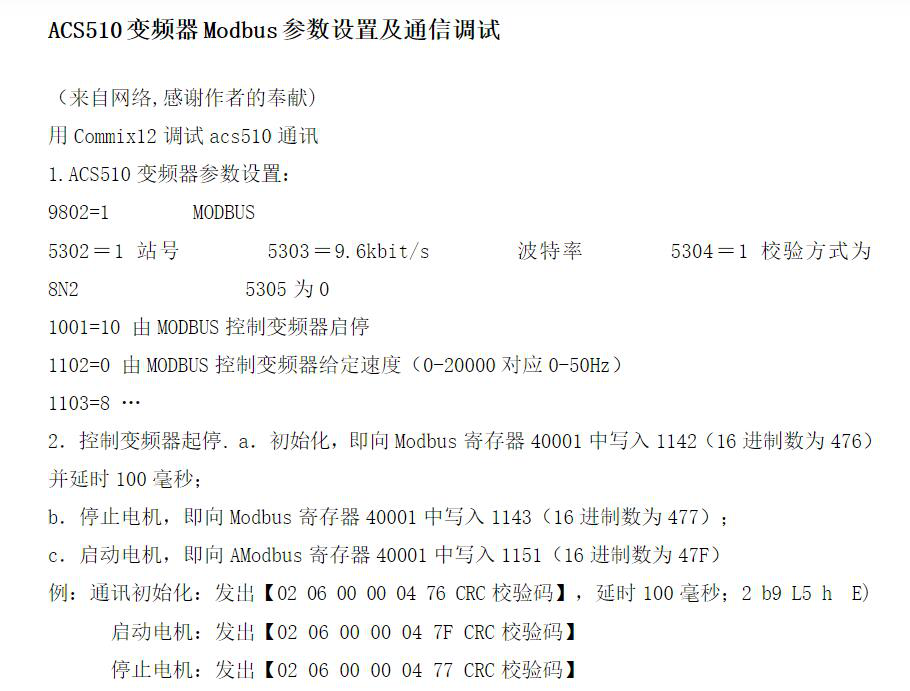

According to the inverter manual description, record the parameters needed for

In this case 485 parameter is set to:

Baud rate: 9600

Data bits: 8

Check digit: no check

Stop bits: 2

Set the inverter controlled by modbus start-stop, given speed

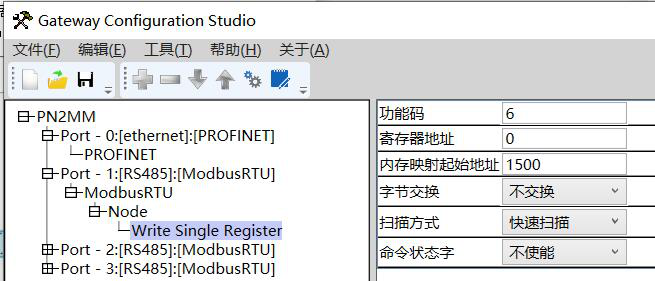

According to the example message display, station number is 2, the use of 6 function code (single register write) register address 0 (note: some equipment register address starting address is not 0, so may need to be done to address offset)

To choose to write a single register

Memory mapped address corresponding to the starting address of the PLC in the Q address in this case, the QB64

After download configuration connection PLC and from station equipment

Of PLC address've written respectively, 1142, 1143, 1151 (decimal) control inverter from the