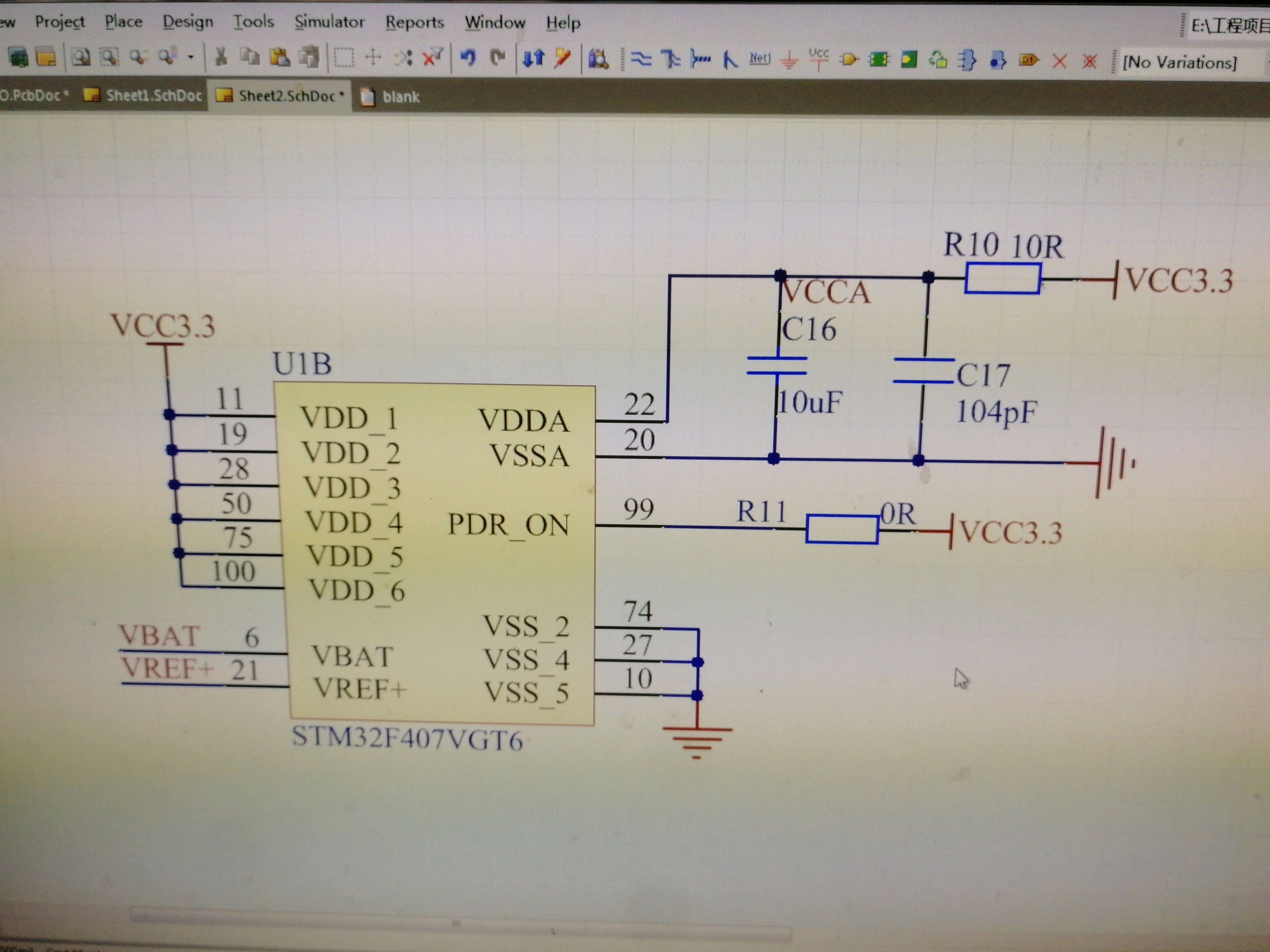

Me all the chip welding, secant want to look at the peripheral circuit where the short circuit, as long as the chip a few 3. 3 v and peripheral circuit cut, any last 3.3 v cut off after the circuit board and chip are not short circuit, what is this?

CodePudding user response:

Didn't see the problem,Before 429 dozen board, dozen two chips on plate welding are short circuit, almost give up, then a done maintenance show the two sentences, the brother of the

1: all the components, the multimeter, measure is negative short circuit?

2: the first is welded on the chip, the short circuit?

Basic can thus find out where is the short circuit part,

CodePudding user response:

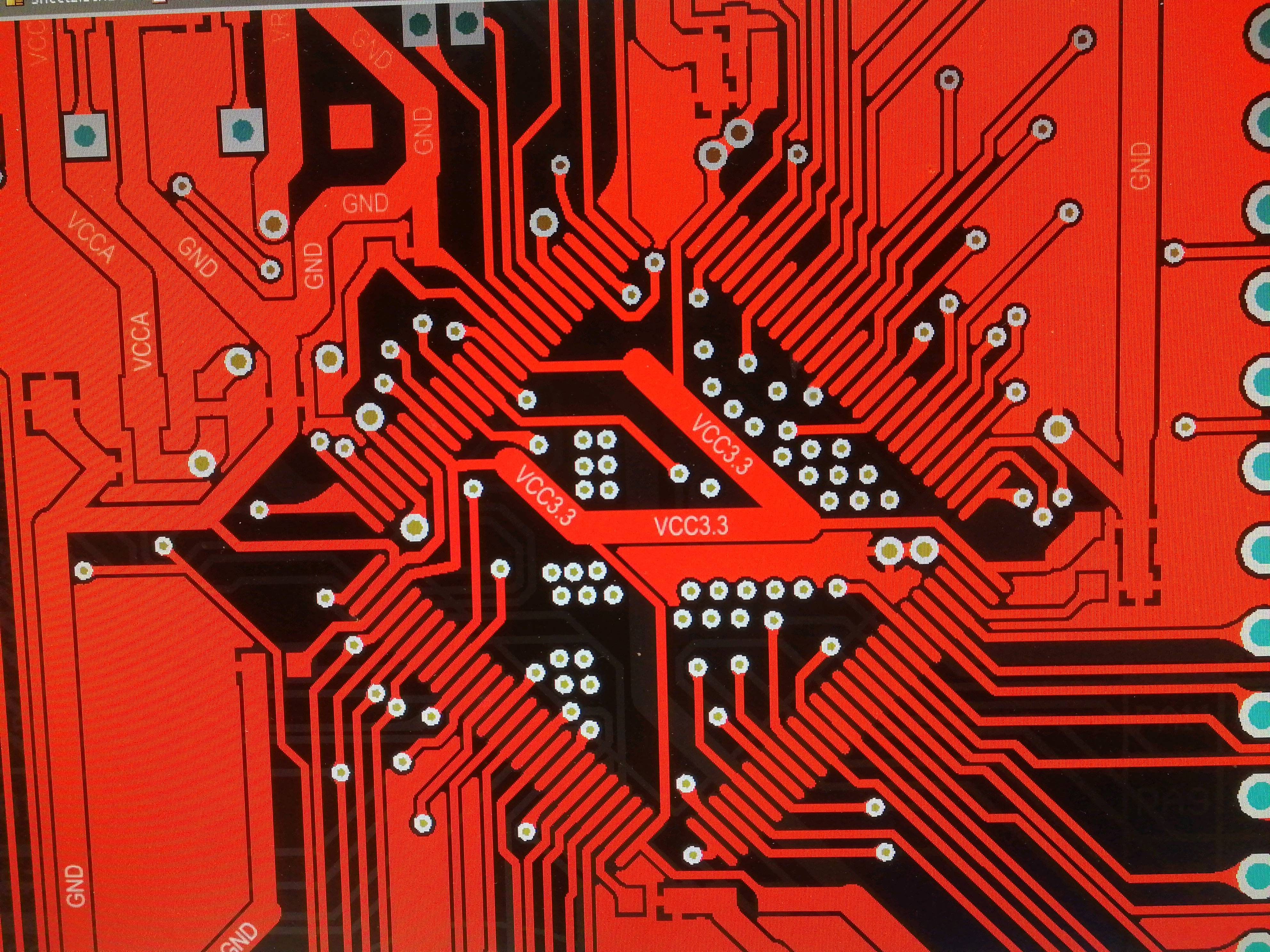

Set up rules for the spacing is how many? How to feel so closeCodePudding user response:

Afraid of not your power supply pins and chip at the bottom of the hole togetherCodePudding user response:

If is a problem of sketchpad, CRC check, can be found that the problem,CodePudding user response:

In board, step by step to check: check the plate is not short circuit, then, for each related to the power of welding device (even a capacitor), measure whether short circuit again carefully, will find the problem ~ ~ ~, the test of time carefully, to ensure that the test is not a problem (sometimes small pin pad, pens and not exposed to determine error is difficult to check) instead of a word: carefulCodePudding user response:

Laying copper bigger safety spacing,CodePudding user response:

Short circuit, you say ever watched dc resistance concrete is how many? Or you dressed on the current super or chip burned? Sometimes because of TVS to protect or dc resistance is small, cause you to misjudge for short circuit, so you want to make sure it really short circuit,CodePudding user response:

The power cord and apply the copper is too close to the hole could gave groundCodePudding user response:

Line and line spacing is too close to, and you the hole is too much, these are all potential ~CodePudding user response:

Pcb has not do ink plug hole?CodePudding user response:

welding problem

welding problemCodePudding user response:

Ensure welding without error, check the schematic diagram again network, on the PCB to VCC, GND took turns to highlight watch it againCodePudding user response:

If not design problem, with the milliohm table, everywhere, can slowly close to short-circuit point, need to be patient, maintenance of production line, the most afraid of be short circuit, it is hard to find a short circuit,CodePudding user response:

1, see you a description of the circuit board should not short circuit, then make sure whether your chip packaging is wrong;2, confirm the welding when there is nothing wrong with one foot;

3, if there is a short circuit welding place;

CodePudding user response:

There is a primary problem to be solved, want to change the PCB rules, laying copper safe spacing to increase, the general situation is greater than 0.25, despite the principle diagram of power supply and ground error, the chips could be damaged, or even tin welding a phenomenon that check 3.3 V and ground network,CodePudding user response:

7th floor right, general multimeter diode, dc resistance less than 70 ohms is considered a short circuit, you'll have to use the dc resistance test &gnd 3.3 V dc resistance in to look at,CodePudding user response:

If really can not find, can be welded on the chip, to power gradually add to the current milliamperes, with thermal imager to find a hot spot, the issuance of theCodePudding user response:

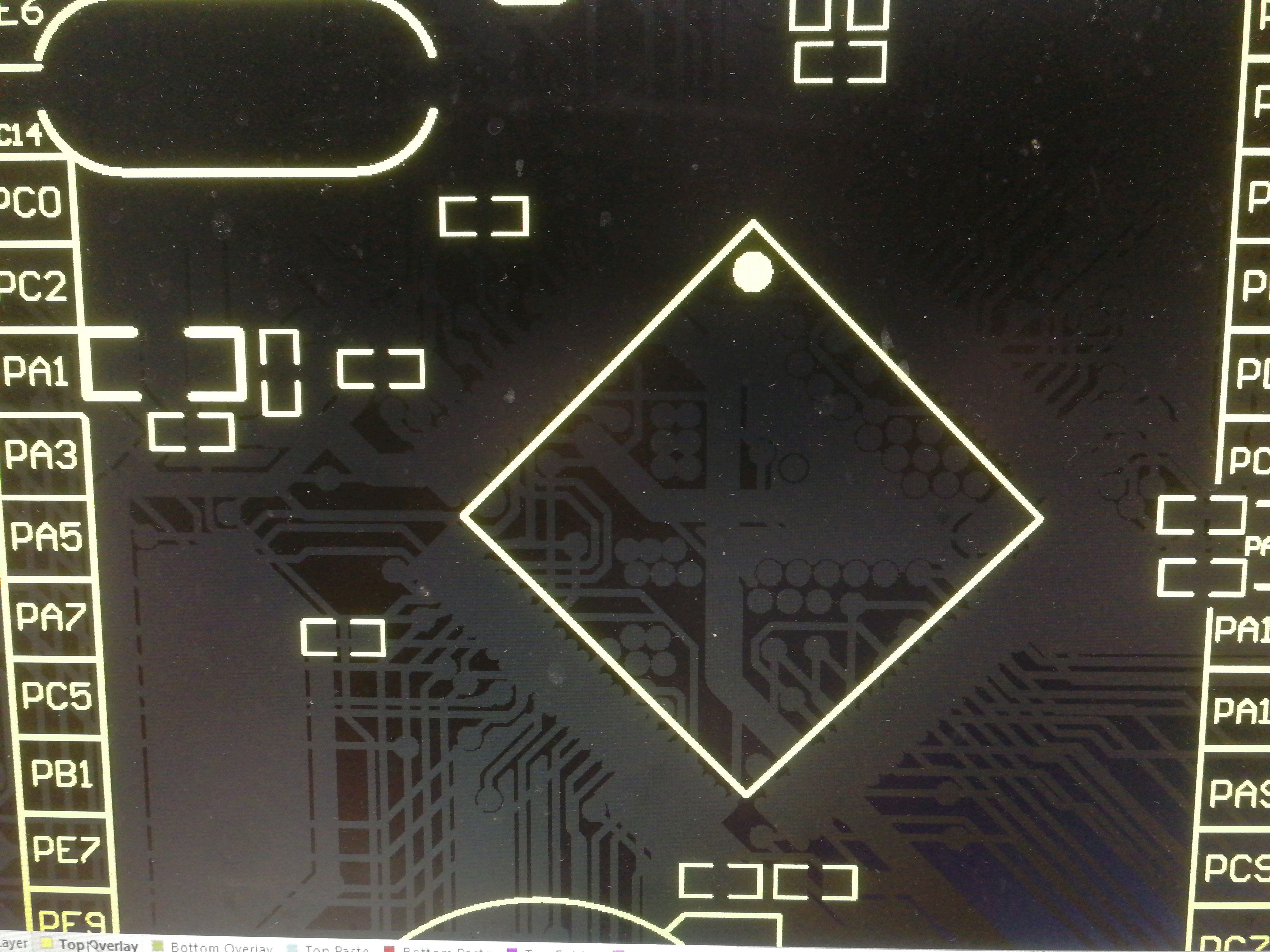

1: confirm the chip foot is normal, the information you give can not judge the first on the left (see part 2) after confirm normal2: close to the power of the foot a hole have dew copper, this is very critical, because they are for my own short circuit welding, and also can't see

3: confirm no problem or a short circuit, it can remove the chips and then confirm whether normal, normal word can weld a bad power supply do not short circuit chip, combined with the power to burn, can see with burning, notice the burning place is short-circuit point

Note: this is to do maintenance of indigenous method and experience, hope to have help

CodePudding user response:

Check if suspected PCB circuit, bare plate short circuit, check whether the line is short circuit is no welding parts,CodePudding user response:

The multimeter measure the dc resistance, not table rang just as a short circuit, some chips power of dc resistance is not higher than 50 ohm, multimeter is loud, not on behalf of the short circuit,CodePudding user response:

Have short circuit test bare plate first, if not, chances are your packaging picture is wrong, or there is a device to put the wrong position, put into the resistance, capacitanceCodePudding user response:

This kind of situation I've met, is somebody else's board,The situation is that the second hit back plate welding, after welding on the multimeter, 3.3 &gnd short circuit, then let me go to help to see a problem,

1. First of all, the bare board test, there is no short circuit phenomenon;

2. Blowing down to 3.3 V ", "no problem, the board or short circuit;

3. Check the chip power supply pins have a dislocation, found no problem line, no solder adhesion phenomenon;

4. The MCU to blow down, clean up the solder, multimeter measurement, not short circuit boards;

5. Measure the MCU pin, discover 3.3 &gnd short,,,

MCU was burned,,, have never met this situation

CodePudding user response:

The power device packaging made a mistake,CodePudding user response:

Is used to detect the DRCCodePudding user response:

The principle diagram of the first check if you have any questions, it would be possible to VCC &gnd label is wrong, this dog chew, also remembered I just learn ha ha ha,