1, tracheal connection

Tracheal connection has two: one is gas interface, marked "SUP" gas supply, the other is a locator output interface, read "OUT" (output), tracheal connection please note don't let the seal belt or dirt into the line, the trachea can be used from 6 mm or 8 mm copper tube, locator factory general with tracheal connector of cutting sleeve type has the phi 6 mm, if you need with phi 8 mm copper tube, please specify when ordering,

2, the circuit connection

1) removed the lid of the box, the input signal is negative and correspondence of junction box is negative, firmly fixed, not loose,

2) flame-proof locator shall ensure that the creepage distance between two wires or 4 mm, signal service entrance can use explosion-proof flexible hose connection, thread of G1/2. The interface, thread length 22 or higher. Can also be used direct cable connection, cable diameter for phi 8 +/- 1 mm, conductor cross-sectional area was> 1.5, cable introduction part shall not be arbitrarily remove sealing plug, gasket, gland nut must be compact, to ensure that the seal, change good after tighten lock screw,

3) must be intrinsically safe locator and associated equipment safety barrier, the installation of safety barrier, debugging must strictly according to the instructions of safety barrier, and the connection wire or cable capacitance <0.03 uF, highest distributed inductance <1.0 mH, the wiring diagram is as follows:

3. Note:

1) open after power off,

(2) the enclosure grounding,

(3) the site shall comply with the explosion-proof electrical equipment safety rules,

(4) flameproof external connection joint should conform to the requirements of the dIICT explosive-proof grade,

(5) intrinsically safe external connection joint should conform to the requirements of the iaIICT5 explosive-proof grade,

6 safety barrier and locator connection wire and cable have to allow distributed capacitance and inductance value is greater than 0.03 uF and 1.0 mH,

All landowners in the cable conductor cross-sectional area S> was 0.5, shield grounding in a safe place,

End of safety barrier installation and debugging must abide by the relevant provisions of the security gate operation instruction,

Adjust the

When the locator after new clothes on the regulating valve, or valve stroke need adjustments when they do not conform to the requirements of the input control signal, the method is as follows:

1) gas pipeline through the relief valve to the actuator, with pressure reducing valve to adjust size of gas supply pressure, make the actuator stem is located in the center of stroke,

2) then, check whether locator and feedback leverage into 90 degrees. Please refer to the "installation" chapter,

3) the gas supply pipe is removed from the actuator, it received a locator (SUP) on gas interface, the positioner output interface (OUT) and connected to the gas chamber of the actuator,

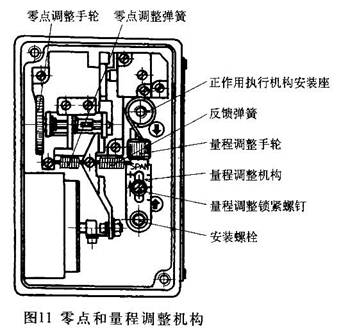

4) zero adjustment steps are as follows: input a 4 ma signal, the executing agency began action (standard 4-20 ma) input signal, adjust the zero point adjustment the handwheel, make zero accords with a requirement,

5) range adjustment range is as follows: enter a 20 ma signal, record the valve stroke, if the trip is less than the rated range, loosen the range adjustment, the screw rotation range adjustment wheel makes the screw press arrow to mobile, will again after adjusted the locking screws,

6) repeat the above step 4) and 5), e., make and achieve zero