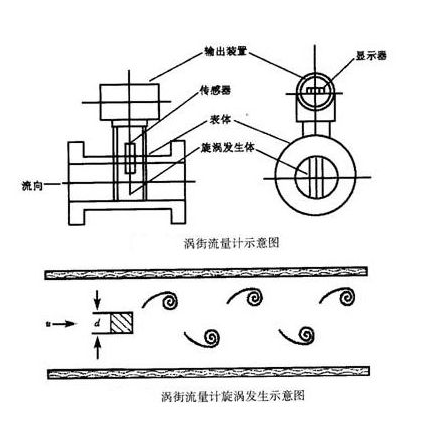

The working principle of

Vortex flowmeter is placed in the fluid a (or more) of streamlining group of fluid, fluid separation alternately on each side of bluff body releases two series of rules of vortex, within the scope of certain flow separation vortex frequency is proportional to the average flow velocity in the piping, by adopting various forms of detecting element to measure vortex frequency of fluid flow can be calculated,

Main functions and characteristics of the

LUGB vortex flow meter with high reliability and long-term stability, because it has a wide measuring range, and high measurement accuracy, low pressure, instrument installation and maintenance is convenient, have no moving parts, simple structure, no mechanical wear, table body by the brand-new appearance design, ontology using precision casting technology, exquisite and beautiful appearance and high temperature resistance, corrosion resistance is strong, LUGB vortex flowmeter signal pulse or commonly used analog signals, anti-interference ability is strong, signal stability for a long time,

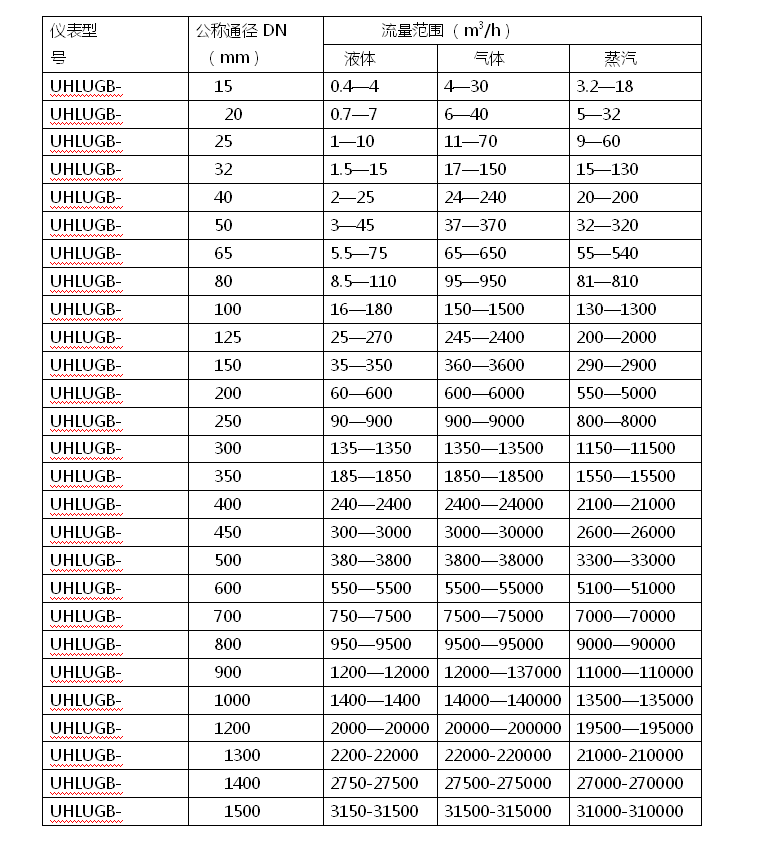

Main technical parameters are as follows:

Measuring medium: liquid, general gas, steam

Nominal diameter: DN15 ~ 12 (tube), 6 ~ DN2000 (plug), above DN2000 caliber supply agreement,

Medium temperature: - 40 ~ 1000 degrees Celsius (room temperature), and 40 ~ 250 degrees Celsius (temperature), and 40 ~ 320 degrees c (high temperature), and 40 ~ 350 degrees Celsius (ultra high temperature)

Nominal pressure: 1.6 MPa, 2.5 MPa, 4.0 MPa (> 4.0 supply agreement)

Accuracy: +/- 1% R, +/- 1.5 R (tube), plus or minus 1.5% R, plus or minus 2.5% R (plug)

Power supply: 12 VDC ﹢ (three-wire system pulse output), 24 VDC ﹢ (three-wire system pulse output type and two wire pulse output type), 3.6 V lithium battery, the double power supply

Body material: 304 (other materials can be supplied from stock agreement)

Protection grade: IP65 (other protective level agreements availability)

Environmental conditions: temperature - 20 to 55 degrees Celsius, relative humidity 5% ~ 90%, atmospheric pressure 86 ~ 106 kpa,

Piping installation

Flange card mounted piping

(1) to spot welding flange and pipe positioning,

(2) the meter off, put flange welding according to the requirement, and clean up the pipe extruding part all,

(3) in the flange of the tank and pipeline on pack sizes within the same sealing washer, will flow in the flange, the flow of traffic marking should be the same as the direction of flow, bolt, then the

Instrument installation plug-in vortex street flowmeter

(1) in the line with gas welding open a slightly less than 100 mm of round hole, and put the round hole burrs around the clear clean, to ensure that the side head rotating fluent,

(2) on the pipe welding on round hole manufacturers provide flange, requirements flange axis perpendicular to the pipe axis,

(3) the ball valve and the sensor installed on the welded flange,

(4) adjust screw, insert depth requirements (ensure that measuring head and the center of a pipeline center axis coincidence), the direction of flow must be consistent with the direction arrow label instructions direction,

5 evenly tighten gland on the screw (note: the degree of tightness of gland determine instrument seal and screw can turn)

6. Check whether the link to finish good, slowly open the valve to observe whether there is a leak, if there is leakage, please repeat the above steps, [/size]