Installation environment requirements

<1> : avoid strong vibration and strong magnetic interference caused by pump or valve pipe vibration can cause measurement error, serious when even will affect the normal measurement instrument, so must be set up in the upstream and downstream 2 d pipe clamp device, support the pipe or hose isolation, strengthen the earthquake effect,

<2> To avoid high temperature heat source and the radiation source directly influence, if the working condition of the scene must be installed, must have heat ventilation measures, such as measuring steam high temperature medium, in order to prevent the converter temperature is exorbitant, should be insulating, to ensure that the meter shell exposed to radiates heat to the outside, to prevent temperature instrument electronic components affecting the service life of flowmeter,

<3> Avoid high temperature and strong corrosive gas environment, of course, if you must install need to set the ventilation measures,

<4> Explosion-proof type of sensor and transmitter installation in dangerous sites, safety barrier, display instrument, power supply, computer and other associated equipment must be installed in a secure environment, sensor and transmitter should be reliable grounding, explosion-proof ground may not be Shared with high voltage grounding protection system,

<5> Flowmeter avoid installed on the overhead long pipeline, due to pipe sag is easy to cause between the meter and flange seal leakage, you must install the working condition of the scene must be in the upstream and downstream of the flow meters 2 d point set pipes,

<6 & gt; Instrument installation best installed indoors, outdoors should pay attention to waterproof, moistureproof, prevent bask in using shield Yang, pay special attention to in the electrical outlet cables should be bent into a U, avoid water along the cable into the amplifier shell,

<7 & gt; Meter should avoid to be installed on the valve outlet is close, because otherwise the valve switch will affect the service life of the flowmeter, serious when damage meter, for the convenience of maintenance, the by-pass pipe should be installed, and especially among some process cannot stop fluid situation,

<8 & gt; Ensure the medium in the pipeline should be in the full package, flow meter can be installed in horizontal or vertical pipe runs, if installed in vertical pipe runs, the measured medium is liquid flows from down to up,

<9 & gt; Flowmeter should be not installed upstream of the flow control valve, but the flow control valve on the downstream of the flow meter,

<10 & gt; Instrument of straight pipe upstream and downstream of the installation points have certain requirements, or will affect the medium flow field in the pipeline, affect the accuracy of measurement instrument,

Pipeline installation requirements

<1> Vortex flow meter has certain requirement for straight pipe upstream and downstream of the installation points, otherwise it will affect the medium flow field in the pipeline, influence the accuracy of measurement, control valve as far as possible not to install in the upstream of vortex flow meter, and should be installed downstream of the vortex flow meter 10 d,

<2> Upstream and downstream piping diameter should be the same, if there is any difference, the pipe diameter Dp and vortex meter Db table body size, should satisfy the following relations 0.98 Db on Dp 1.05 Db or less or less, the downstream piping should be with concentric flow meter table body size, not alignment between them should be less than 0.05 Db,

<3> Between the instrument and the flange gasket, not protruding into the tube when installation, the inner diameter should be 1-2 mm larger than table inside diameter,

<4> When measuring high temperature, low temperature medium, should notice heat preservation measures, the converter internal casing (header) high temperature should not be commonly more than 55 degrees Celsius; Easy to appear converter internal condensation at low temperature, reduce the insulation resistance of printed circuit board, affect the normal work of the instrument,

<5> Instrument in the line can be horizontal, vertical or inclined installation,

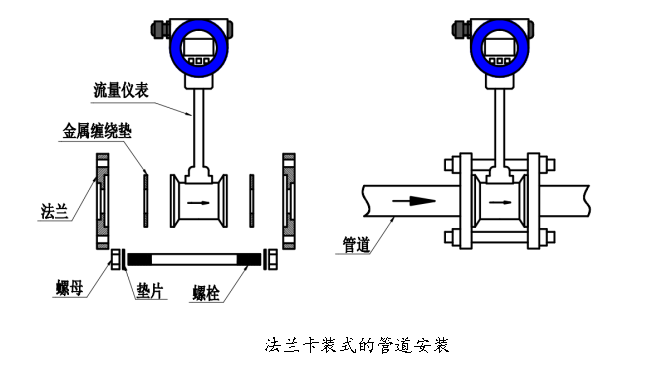

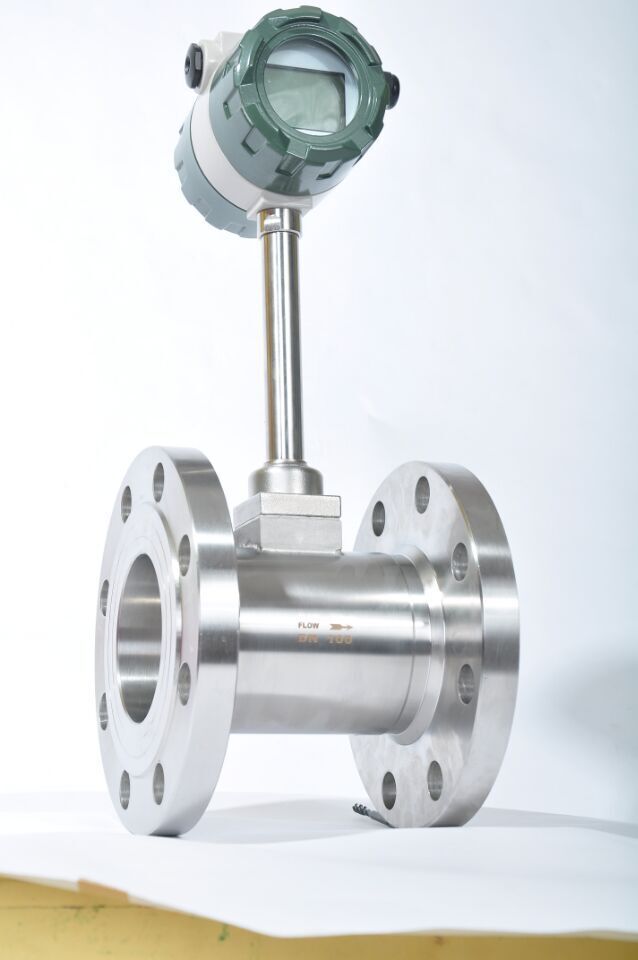

Flange card mounted pipeline installation requirements

<1> For flange and pipe welding positioning,

<2> 'll take out the flowmeter and the flange welding, according to the requirement and clean up the pipe extruding part all,

<3> In the flange of the groove on the same seal gasket and pipe sizes, will flow in the flange, the flow of flowmeter standard should be the same as the direction of flow, the bolt, then the

Insert the instrument installation requirements

<1> In line with gas welding open a slightly less than 100 mm of round hole, and put the round hole deburring around clean, to ensure the measuring head rotating fluent,

<2> Round holes in pipe welding manufacturers provide flange, requirements flange axis perpendicular to the pipe axis,

<3> The ball valve and the sensor installed on the welded flange,

<4> Adjustment screw, the insert depth requirements (ensure that measuring head and the center of a pipeline overlap) the central axis, the direction of flow must be consistent with the direction arrow label instructions,

<5> Uniform tighten gland on the screws, (note: the degree of tightness of gland determine instrument seal and screw can turn)

<6 & gt; Check each link to finish good, slowly open the valve to observe whether there is a leak, special attention should be paid to the personal safety) if there is leakage, please repeat the step,

Install and use notice:

<1> Flowmeter of the flow arrow direction should be in the same direction of fluid flow and the pipe,

<2> Pipeline installation flowmeter to conform to the rules (with), otherwise it will affect the measuring accuracy of flowmeter, serious when damage flowmeter,

<3> In the installation of traffic time, in the process of welding flange or the pipe, flowmeter must not on the pipeline, in order to avoid damage to the interior of the flowmeter accessories,

<4> Flow meter before operation must be carefully check meter installation and wiring, etc are correct,

<5> So DC24V power supply of the flowmeter, be sure to first in advance using the multimeter, detect whether the DC24V power supply for alternating current (ac) ingredients, such as don't contain ac component test connection, will cause the circuit board burn out, can't use: be sure to guarantee the power supply is DC24V,

<6 & gt; Observe LCD screen after turning on the power supply for traffic, according to

<7 & gt; Slowly open the valve and open the time should not less than 2 minutes, to a smaller pressure to stop, to observe whether there is leakage around the sensor phenomenon occurs, and watch the LCD screen whether there is traffic, according to

<8 & gt; If is normal, the larger valve, stable after a period of time, observe whether the flow of liquid crystal display screen is normal, [/size]